eddylab GmbH is a manufacturer and sensor specialist in the field of high-precision displacement measurement technology and your contact for application advice, sales, service and repair.

On this page you will learn how Digital Gauges work according to the Magnescale principle. These sensors are used in industrial applications with the highest demands on accuracy and must at the same time be unaffected by temperature fluctuations and resistant to vibration, moisture, dirt and external interference fields.

Digital Gauges based on the Magnescale principle have several MR elements that work according to the GMR (giant magnetoresistance) effect. The MR elements change their electrical resistance depending on the strength and direction of the magnetic field strength (flux density) of an external magnetic field.

The external magnetic field is formed by a permanently magnetised neodymium-iron-boron scale with alternating north-south pole division, which is guided past the MR elements by the external movement of the probe.

The resistance change in the MR element is based on the deflection of the direct current path by the magnetic field strength (flux density) due to the Lorentz force. Due to the magnetic field strength, the current does not flow in a straight line through the element on the shortest path, rather it runs in zigzag lines, which have an increased path and thus higher resistance. The higher the magnetic field strength, the more pronounced the zigzag current course and consequently the increase in resistance. In order to produce a high resistance change and thus high sensitivities of the MR elements, the individual MR elements of the Magnescale sensors are made of bismuth. This is a highly diamagnetic metal with the greatest resistance change (over 100 %) due to external magnetic fields compared to other elements. This makes it possible to measure flux densities in the range of 0.0001...5 mT with high precision. Bismuth MR elements are therefore particularly well suited for sensor technology.

The MR elements are operated via Wheatstone measuring bridges. The MR elements are spatially arranged in such a way that the guided movement of the scale at the MR elements produces three sinusoidal signals offset by 120°. By simultaneously evaluating the sine signals, the direction of movement can be detected and a particularly effective error correction (amplitude, phase and offset errors) can be carried out. This guarantees the highest accuracies in the submicrometre range and offers significant advantages compared to conventional systems with only two sinusoidal signals offset by 90°.

An evaluation unit interpolates the sine signals to an incremental TTL output signal with specified resolution (transistor-transistor logic).

The Digital Gauges are characterized by extremely good linearity. The maximum permissible measuring error is defined over the entire measuring range. Each device is delivered with a calibration certificate. For particularly high demands on accuracy, eddylab GmbH makes a selection of especially outstanding sensors on request.

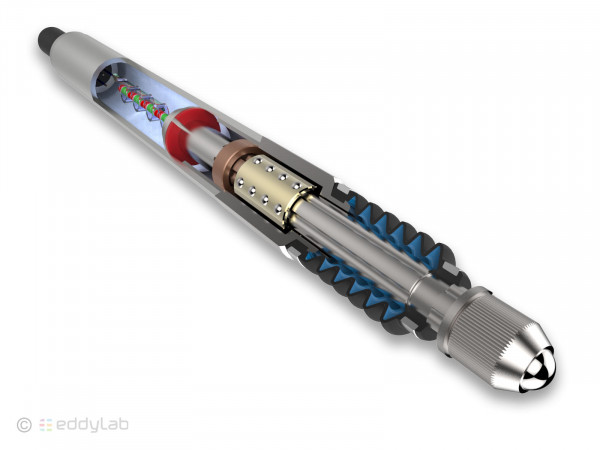

The Digital Gauge DK800S series offers special precision due to the newly developed shaft groove bearing. The balls of the linear ball bearing run in round grooves that are precisely incorporated into the plunger. This results in a 5-fold higher bearing load capacity compared to conventional ball bushings. In addition, this bearing technology allows a smaller bearing clearance between the plunger and bearing bush. Due to the shaft groove bearing, the plunger is rotationally secured without play. This makes the DK800S Digital Gauge even more precise and resistant and, thanks to the lower friction, achieves a service life of over 130 million cycles.

DK800S with shaft groove bearing

DK800S with shaft groove bearing

The advantages of the shaft groove bearing:

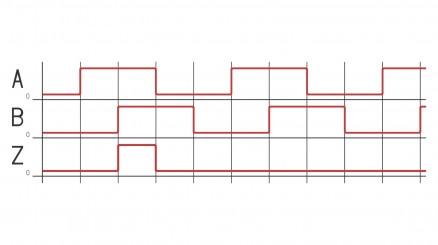

Similar to incremental encoders, the pulses of the measuring system are output as a TTL signal. The TTL signal consists of high and low levels, which differ in their voltage level. While a high level represents a voltage value close to the operating voltage of 5 V, the low level has a voltage value of almost 0 V. Analog voltage signals are somewhat distorted and distorted on their transmission path (cable) with regard to gain and offset. Therefore, TTL signal output is particularly suitable, since the signal level is independent of the accuracy of the measuring system. It only has to be determined whether a high or a low level is present, which voltage value this is exactly does not matter. Only the discrete states high or low are transmitted. The resolution of the incremental measuring system can thus be transmitted without interference. If the plunger of an incremental probe with a resolution of 0.1 µm moves by 1 µm, for example, 10 pulses are output (1 pulse per 0.1 µm). The output signal is formed by two channels A and B, which are output 90° out of phase. A pulse always corresponds to a rising or falling edge of the A or B signal (4-fold edge evaluation).

ABZ-pulses

ABZ-pulses

The DK and DK800S series from Magnescale also have a reference point (Z signal). This can be used for referencing the system. For example, in an end position, the counter reading in the machine control or the display of a counter display can be set to zero with the Z signal.

TTL output signals are widely used industrially and can be processed via counter inputs or encoder inputs of machine controls (PLC), counter displays or measuring cards for computers. This allows a simple and trouble-free adaptation to all common machine controls.

Magnescale gauges have excellent vibration and shock resistance because no sensitive glass scale is installed. The basic material of the scale is neodymium-iron-boron. This is coated with a protective layer and then hardened. Breakage of the scale due to strong shock loads is not possible. This is an extraordinary advantage compared to gauges with glass scales.

The housings are robustly made of stainless steel and die-cast zinc. The shock bearing of the DT-series is a plain bearing, the high-precision DK and DF-series are equipped with linear ball bearings. The plungers of the sensors are hardened and have a hard chrome coating. This extremely increases the wear resistance and the service life is over 100 million cycles. The plungers of the DT series receive an additional, friction-reducing DLC sliding layer.

Digital touch probes are available in different protection classes up to IP67. This allows the use in humid environments. Usually, the plunger is protected by a bellows or the plunger bearing is designed with a system of different shaft sealing rings. This makes the displacement transducers very resistant to contamination with water, oil and dust and ensures a long service life even in harsh industrial environments. Furthermore, the Magnescale measuring principle is insensitive to contamination, as scanning is performed via magnetic pole pitch and detection via an MR element. This is a decisive advantage over optical measuring systems with glass scale.

For pure laboratory environments with the highest demands on absolute accuracy and repeatability, the devices are designed without any protection class. This has the advantage that the bearing of the plunger can be executed almost frictionless, thus avoiding a stick-slip effect. The smallest movements in the submicrometer range with changing direction of movement are detected with high precision and without hysteresis.

The digital probes are optionally available as pneumatically operated variant or vacuum variant. Sensors of the DT series that can be actuated by compressed air are equipped with an optional air lifter that retracts the probe tip in the depressurized state. This reliably prevents collision in the passive state. When compressed air in the range of 2.5 ... 7 bar is applied, the plunger is extended for measurement. Likewise, the applied pressure can be used to set the measuring force of the probe tip on the object.

The extension speed can be adjusted via the throttle valve in order to avoid bouncing of the probe tip on the measuring object or to achieve a gentle touchdown in case of particularly sensitive measuring objects. Devices of the DK800 series (version L) have a direct air connection that draws in the plunger via vacuum. In the vacuumless or depressurized state, this is moved out by the internal pressure spring for measurement.

Operation with air lifter:

The maximum operating temperature of 50 °C qualifies the digital gauges for both pure laboratory conditions and industrial environments. High-precision measurements are often required for quality assurance, such as for component inspections in incoming goods and for continuous monitoring of manufacturing processes and assembly operations. The digital gauges have a very compact design and can be configured in a variety of ways so that they can be used almost universally in machines, fixtures, test stands and factory automation systems.

The Digital Magnescale Gauges can be operated as "stand-alone" as well as in connection with multifunctional displays or interface modules. This provides many quick and easy installation options. Likewise, Magnescale gauges with TTL interfaces can be connected to different controllers or displays from a third-party manufacturer.

Multi-channel interfaces allow up to 100 gauges to be operated simultaneously in an economical and space-saving manner. The CC-Link and EtherNet interface of the MG40 series guarantees very fast and reliable transmission of all measured values and is compatible with Beckhoff controllers.

In addition, eddylab GmbH also offers flexible multi-interfaces for the Digital Gauges. Up to 64 gauges can be connected via an RS-232C interface, which is also optionally available with a BCD interface.

Via multi-function displays or via interface module the data can be recorded directly with the PC.

Modular interface module with Ethernet

The MG80-MA interface module enables not only data transfer to the PC via Ethernet but also storage and parameterization of measurement data and parameters on SD card or USB stick.

Fieldbus-compatible interface units MG80-NE/EI/PN

Up to 16 counter modules (MG-80-CM) for measuring probes can be connected to each MG80-NE interface module (Ethernet). Up to four MG80-NE modules can be linked and this enables an overall configuration of up to 64 DK and DT series probes. The MG80-EI (Ethernet IP) and MG80-PN (Profinet) interface modules can be linked to 255 modules, allowing up to 4080 probes to be read.

User-friendly HMI functions

The new LT80 7-inch touch-screen LCD display shows I/O status, add/sub results and current measurement modes, and is easy to use thanks to the multilingual support and the clear menu navigation.

Interface module MG80-MA with touch-screen display LT80

The DT gauges offer the most cost-effective entry into the world of Digital Gauges for measuring ranges of 12 and 32 mm. The rectangular housing has a short overall length and the clamping shank has a clamping diameter of 8 mm. The probe can be mounted directly via the two housing holes or via the 8 mm clamping shank. This series is designed as a spring loaded probe and can also be operated pneumatically. A resolution of 1 µm and an accuracy of ±6 µm is achieved.

The DK Gauges are designed in a particularly robust construction. The housings have an enlarged diameter with 20, 25 and 32 mm and stable measuring plungers with diameter 6 to 8 mm depending on the measuring range. The instruments with 155 and 205 mm have no internal spring. The plunger is held to the object by the magnetic force of the neodymium magnet attached to the plunger. This eliminates the spring force on the object and leaves only minimal frictional resistance of the plunger seal acting on the object.

Digital Gauge DK10PLR5

With an effective measuring range of up to 110 mm, even rather untypical measuring ranges for spring loades probes can be realized. The DK155 and DK205 series cover a measuring range of 155 and 205 mm, respectively. Instead of an internal spring, these displacement transducers use a magnetic probe tip to attach the plunger to the measured object.

The high-precision digital gauges of the DK800S series offer a resolution of 0.1 µm. Their slim design with a shaft diameter of 8 mm makes them universally applicable, even in confined installation situations or dynamic applications. The DK800S series is available in many different versions. A choice can be made between radial and axial cable output. In addition, flanged versions with convenient mounting options are available. Pneumatically driven variants with compressed air or vacuum function are also available.

Digital Gauges DK800S series

With the new measuring software MeasureViewer for USB Digital Gauges measured values can now be monitored and visualized optimally thanks to a clear display with multiple options such as numerical display, horizontal and vertical bar display or analog meter display.

The measured values are displayed in a real-time chart display. Different measuring modes can be selected such as current, maximum, minimum, and P-P values.

Measurement values and judgements results are available via key press or timed intervals in CSV format.

More Information: